Gain the autonomy to take charge of your company’s future. Being able to respond quickly to customer expectations. Take up challenges, anticipate and create the needs of tomorrow. Here’s a three-point definition of the Satab Lab, Satab’s integrated R&D team.

To (re)discover the Satab Lab from the inside, we interviewed Daniel Arnaud, the ‘head’ of this innovation collective.

Satab : How did the Satab Lab come about?

Daniel Arnaud : Satab Lab was set up in 2005 at the instigation of the general management to challenge, centralise and promote innovation and develop the narrow textiles business.

Satab :What are the aims of the Satab Lab?

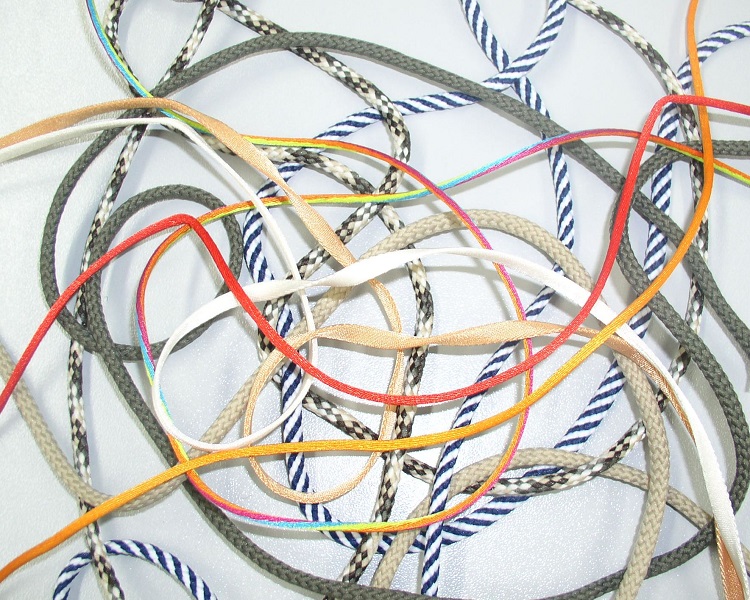

D.A :The aim of the Satab Lab is directly linked to Satab’s raison d’être: “To create desires and drive new uses for narrow textiles”. For example, a range of eco-responsible narrow textiles, Respect Line, was designed and developed as part of the Satab Lab, with the help of a network of suppliers and service providers met during training courses, trade fairs and collaborative projects.

Satab : In practical terms, how does this R&D collective work?

D.A : Satab Lab is a team dedicated to R&D and innovation.

But in general, it all starts with a desire to be in step with, and even ahead of, our market. Satab Lab has seconded an engineer to keep a constant, cross-functional watch on the textile industry.

Currently, as part of our N.E.T. 2024 corporate project, she is focusing on yarns made from bio-sourced or recycled materials, with production processes that consume less energy and water. That’s what Satab Lab is all about! Looking to the future to offer products and manufacturing processes that make a lasting contribution to a better world.

At the same time, Satab is also a member of an association of non-competitive partners. Based on the values of trust and transparency, members pool their research activities to gain faster, more efficient access to new product and market developments.

This 360° view of the textile industry means that new product and process development ideas can be passed on to Marketing and General Management. These are selected and prioritised, then deployed within the Satab Lab.

Satab : What projects does the Satab Lab handle?

D.A :

We can classify the projects we support into three categories:

– Internal product or process development projects incorporating our catalogues or know-how

– Collaborative projects, such as the PSPC “Projets Structurants Pour la Compétitivité” (Structuring Projects for Competitiveness), which enable us to meet and collaborate with private and academic partners on a breakthrough innovation.

– Projects brought in by our customers, mainly in the industrial sector, to develop new products.

Satab : What is your own definition of the Satab Lab?

D.A : Satab Lab is all about 360° openness, interactive sharing and an inexhaustible source of ideas to help your business grow.

To find out more about Daniel Arnaud :

“At the end of a degree in mechanical engineering, my first experiences revolved around automotive subcontracting, foundry work and machining of mechanical parts. It was in four companies in the Lyon region, in a sector that was well ahead of its time in terms of quality, that I discovered Quality Assurance and in-process control, as well as high-precision three-dimensional control in the laboratory. For the record: I took my first steps in quality shortly before the first ISO 9001 standard came into force.

“At the end of a degree in mechanical engineering, my first experiences revolved around automotive subcontracting, foundry work and machining of mechanical parts. It was in four companies in the Lyon region, in a sector that was well ahead of its time in terms of quality, that I discovered Quality Assurance and in-process control, as well as high-precision three-dimensional control in the laboratory. For the record: I took my first steps in quality shortly before the first ISO 9001 standard came into force.

This experience in control enabled me to join the Lafuma company in the early 90s, where over time I took on responsibility for quality management, combining a professional life with a passion for sport and the mountains.

Following a reorganisation, I left Lafuma and took up an engineering course in project management at CESI in Ecully.

When I left the school, at the age of 40, I joined Satab to support the ISO 9001 certification we obtained in 2006. As well as quality, I was responsible for safety and environmental management, and later for managing the Research and Development department.

In September 2018, the position of Industrial Director became available and the General Management entrusted me with this function, which includes the R&D and innovation department, production and related production services.